We highly integrate excellent motor technology, drive technology, encoder technology and reducer technology Together, we provide excellent solutions for the development of robots!

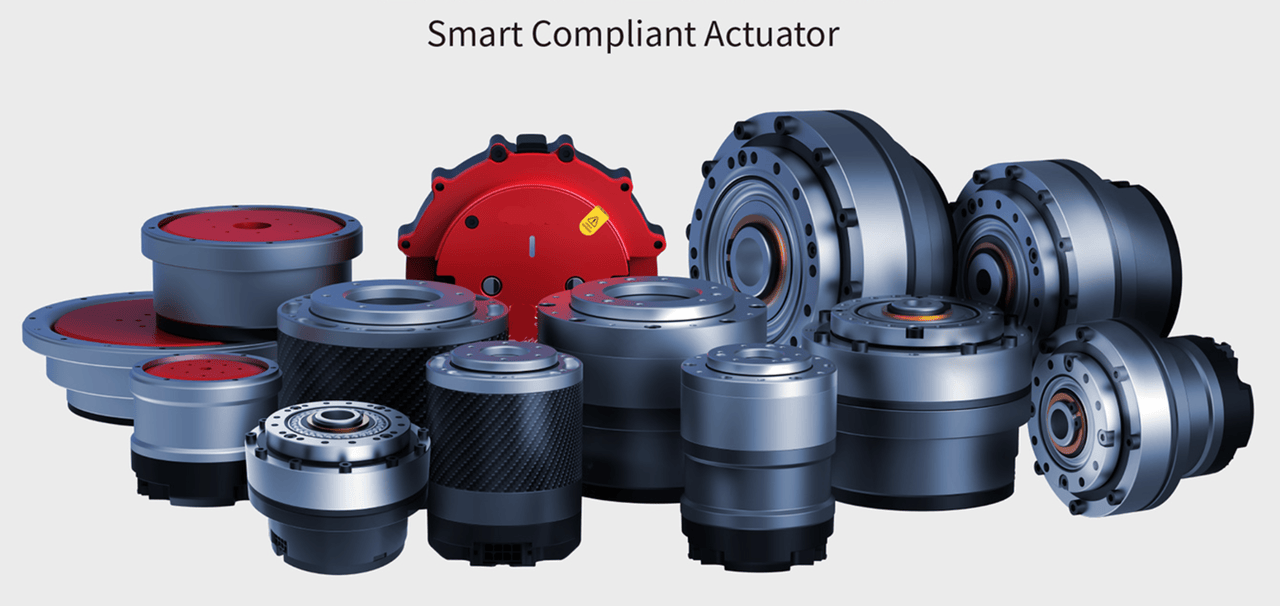

The world's most advanced intelligent flexible joint,Our intelligent flexible joints actuator are intelligent, highly integrated, and advanced intelligent flexible joints with flexible and safe control capabilities.

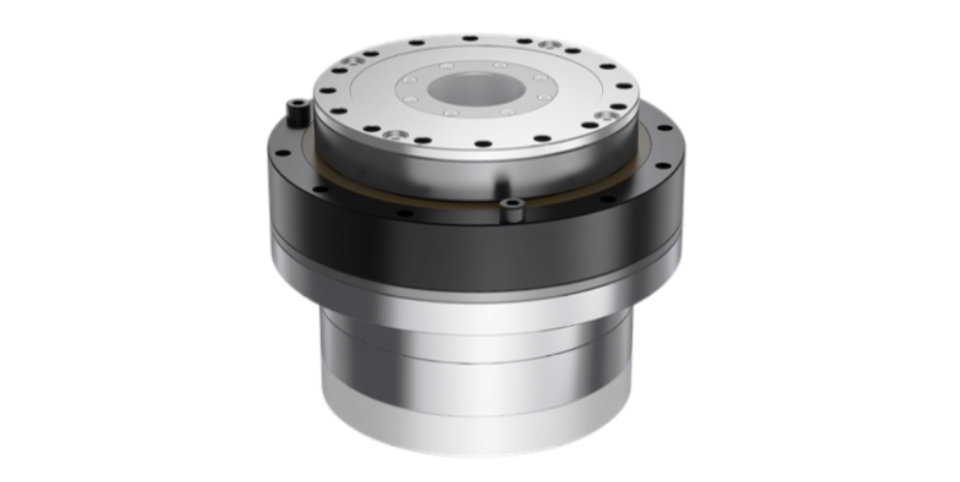

The integrated joint module integrates the driver, motor, reducer, encoder and sensor into one module. This design not only saves space, but also reduces assembly complexity and improves structural compactness and lightweight.

Through modular design, the robot joint module can flexibly adjust its weight and function according to task requirements. Adopting building block design to achieve lightweight goals with high cost performance and provide higher performance redundancy

Using an efficient planetary reducer or harmonic reducer can reduce mechanical complexity and weight and improve overall performance. For example, some high-performance joint modules integrate lightweight motors and high-precision encoders to further achieve lightweight

The flat robot joint module includes a casing and a DC servo driver, an absolute encoder, an output shaft, an outer rotor torque motor and a harmonic reducer set in the casing; the harmonic reducer is set on the inner ring of the outer rotor torque motor. , DC servo The driver is set on the harmonic reducer, and the external rotor torque motor drives the output shaft to rotate through the harmonic reducer. The output shaft cooperates with the absolute encoder through the gear; the front side of the casing is equipped with a crossed roller bearing, and the output shaft is connected to the harmonic reducer. Crossed roller bearing fits

The efficient design of the integrated drive system reduces transmission losses, making the robot less energy-consuming and more stable in operation. Especially in multi-degree-of-freedom robots, drive integration reduces system inertia and improves movement accuracy. The highly integrated and miniaturized design of the drive integrated module makes it suitable for wide application in the fields of humanoid robots, medical robots and industrial automation.

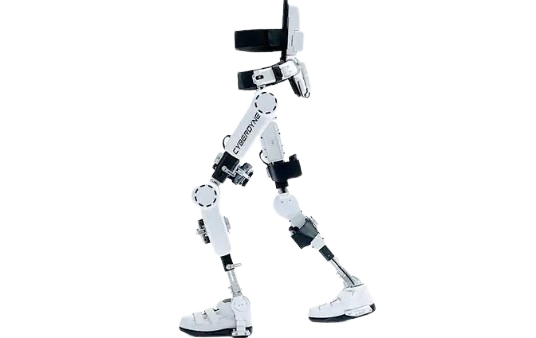

Rehabilitation training equipment: Suitable for early and mid-term rehabilitation training for patients with various types of lower limb dysfunction. It can achieve weight loss, standing, walking in place, (complete machine) indoor and outdoor flat walking, gait training, and functional assessment. Application scenarios: cerebral palsy, hemiplegia, myasthenia, spinal cord injury, myelitis, movement recovery after osteoarthritis surgery

Powered exoskeleton: Powered exoskeleton robot is a new wearable lightweight robot. It can not only help disabled people regain their hands-on and walking abilities, but is also expected to prevent patients from developing pressure ulcers caused by sitting in wheelchairs for long periods of time. It can also improve heart health, exercise muscle strength, and relieve depression, etc.

Disease screening: industry pain points: 1. Unlike the static images of CT and MRI, ultrasound is a low-resolution imaging and needs to be interpreted in a dynamic process. There is a certain subjectivity in the ultrasound doctor's examination process, and the standardization issue remains unresolved. 2. Due to factors such as the subjectivity of ultrasound doctors in reading images and the large number of dynamic image interference factors, ultrasound testing results are very dependent on the doctor’s experience, and the gap of high-quality doctors urgently needs to be filled.

Two-arm robot: The harmonic reducer series actuator is built, and the arm length has a large range of movement and can be used in industrial, laboratory and other scenarios.

Parallel robot: The characteristics of parallel robot are no cumulative error and high precision; the driving device can be placed on a fixed platform or close to the fixed platform, so that the moving part is light in weight, high in speed and has good dynamic response.

SCRAR robot: has multiple degrees of freedom. This planetary reducer series joint module includes translational freedom along the X, Y, and Z directions and rotational freedom around the Z axis. It can be equipped with end fixtures, vision, laser and other equipment for different scenarios. of use. 1. Adapt to complex processes: rapid sorting, transportation, assembly, dispensing, etc. of various materials; 2. Can automatically adjust the appropriate acceleration and deceleration according to the posture of the arm to ensure smooth movement; 3. Can be used with high-precision visual inspection, The alignment system cooperates with high speed, high precision and high stability; 4. The integrated design of the robot body and controller can effectively utilize the installation space.

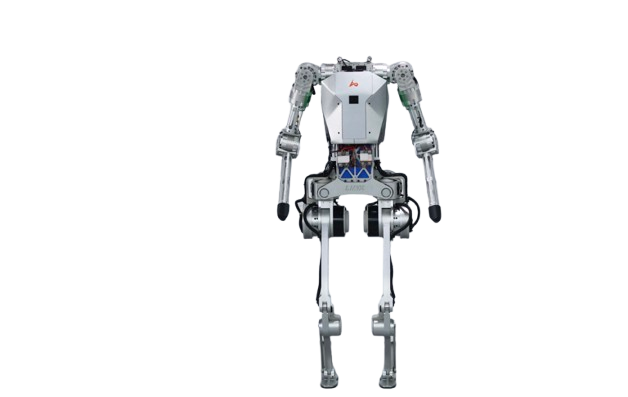

Humanoid bionic robot: Our company's shutdown module actuator can be applied to all joints of the humanoid robot's body to provide concierge, reception, guidance, nursing, promotion and other services to all types of customers.

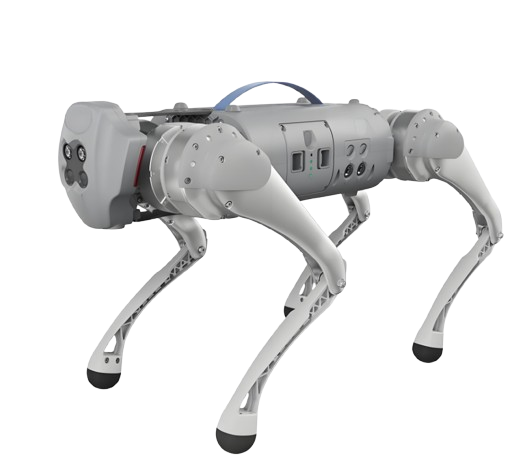

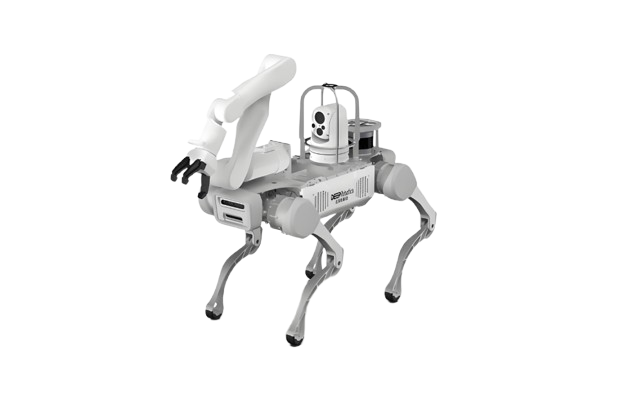

Quadruped bionic robot: Our company’s planetary reducer series joint actuators. It can meet the needs of a quadruped robot with a total of 12 degrees of freedom, and is used to provide communication between the actuator and the upper controller and IMU data. It can be used in medical treatment, material transportation, industrial consumption, environmental exploration, and resource collection.

Entertainment bionic robot: Our company's planetary reducer series joint actuators. It can meet the needs of bionic robots with a total of 10 degrees of freedom, and can be used in entertainment parks, theme parks, science and technology museums, etc.

Switch room operation: Switch room operation robots are mainly used in substation switch rooms and other environments to complete emergency opening operations and regular switching operations of switch cabinets. It has functions such as autonomous navigation, precise positioning of terminal working tools, intelligent identification of equipment status, autonomous emergency opening, transfer knob switch, button operation, ground knife, handcart rocking in and out, etc. It can replace or assist manual operation tasks and greatly reduce work. Reduce the workload of personnel, shorten troubleshooting time, ensure the personal safety of workers and the safety of the power grid, and reduce the occurrence of power accidents.

Substation indoor inspection: core functions include: intelligent image recognition, high-definition video real-time monitoring, high-definition infrared temperature measurement, voice interaction and sound pickup detection, temperature and humidity detection, gas detection, data analysis and report generation, fault alarm, can be replaced Or assist manual operation tasks, greatly reducing the workload of staff, shortening troubleshooting time, ensuring the personal safety of workers and the safety of the power grid, and reducing the occurrence of power accidents.

Indoor inspection: Mainly used in indoor inspection environments, equipped with a self-developed multi-degree-of-freedom robotic arm, with intelligent sensing, autonomous inspection, image recognition, infrared temperature measurement, partial discharge detection, gas detection, audio recognition, and voice intercom Functions such as these can replace or assist manual operation tasks, greatly reduce the workload of workers, shorten troubleshooting time, and protect the personal safety of workers from accidents.

CNC workbench: Use 3 SCA to build a three-axis motion platform CNC. SCA supports universal CNC controller interface logic and uses the ABI binary interface to realize the action control and position control of the actuator by controlling the start, stop and pulse signals of the actuator. , can run mainstream machining programs, has good heat dissipation, and does not require a break. There is a sensor signal transmission interface that can achieve dual position detection with higher safety and accuracy. It can be used with various CNC systems such as Huazhong, Siemens, Mitsubishi, FANUC, Kanedi, Guangzhou CNC, and Xindai. It can be widely used in numerical control lathes (CNC), laser engraving, and woodworking engraving, providing assistance for automation and mechanical processing.

Carbon fiber printing equipment: The light weight and high strength-to-weight ratio of carbon fiber composites make them an ideal replacement for some metal parts and structures because they can reduce material costs and improve mechanical properties.

Logistics automated code scanning: A three-axis robotic arm built with three harmonic joint modules was successfully used in the automatic code scanning work of the automated production line, replacing the traditional servo and pioneering the application of modules in the field of automation.

Automated hoisting: In automation projects, the small size and large torque that cannot be achieved by servo in the special narrow space are replaced by harmonic modules, and the module is successfully flipped to hang 30 kg objects for a long time, testing the neck of the module's mechanical structure bearings. load capacity.

Civilian drones: currently used in aerial photography, agriculture, plant protection, micro-selfies, express transportation, disaster relief, observing wild animals, monitoring infectious diseases, surveying and mapping, news reporting, power inspections, disaster relief, film and television shooting, creating romance, etc. , greatly expanding the uses of drones themselves. UAVs built using servos and ordinary motors can be completely replaced with SCA, and the performance and cost-effectiveness will be greatly improved.

Boiler damage inspection: The AGV trolley built with flexible actuators and mechanical operating arms are used in the damage inspection of waste-burning boilers, replacing manual operations in extremely special environments, reducing costs and increasing efficiency.

Assisted driving: Assisted driving vehicles use on-board sensors to sense the surrounding environment of the vehicle, and control the steering and speed of the vehicle based on the obtained information about the road, vehicle position and obstacles, so that the vehicle can drive safely and reliably on the road. . Our company's high-precision version of the module has high accuracy and uses Pro series modules to control the car's steering wheel, brakes and accelerator, thereby achieving precise control of direction and speed.

AGV application: The driving and steering parts of the AGV are built with two joints. One AGV has four wheel sets and uses 8 SCA. It is widely used in warehousing, manufacturing, post offices, libraries, ports and terminals, airports, tobacco, medicine, food, chemical industry, hazardous locations and special industries. Features: 1. Can be charged independently and operates continuously for 48 hours to improve work efficiency; 2. Reduce manual dependence and reduce costs; 3. Improve the level of intelligent management; 4. Multi-level security measures for software and hardware to ensure machines, personnel and equipment Safety.